GGBS is a fine powder, used in concrete as "cement", major use in ready mixed concrete (RMC) or in the production of Portland slag cement. GGBS replaces a substantial proportion of normal cement (Ordinary Portland Cement) in RMC. The mixing varies from 30% to 70% approximately (generally 50%). The higher the proportion, the better is durability for concrete. GGBS is also in other forms of concrete including site-batched and pre-cast.

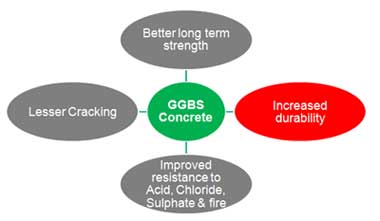

Replacement of Portland Cement by adding up to 70% GGBS, reduce cement content in concrete from about 530 Kg/m3 to 160 Kg/m3 and despite of this large reduction of cement in concrete, ultimate strength is not affected, also considerable improvement in durability properties is observed.

GGBS is a fine powder, used in concrete as "cement", major use in ready mixed concrete (RMC) or in the production of Portland slag cement. GGBS replaces a substantial proportion of normal cement (Ordinary Portland Cement) in RMC. The mixing varies from 30% to 70% approximately (generally 50%). The higher the proportion, the better is durability for concrete. GGBS is also in other forms of concrete including site-batched and pre-cast.

Replacement of Portland Cement by adding up to 70% GGBS, reduce cement content in concrete from about 530 Kg/m3 to 160 Kg/m3 and despite of this large reduction of cement in concrete, ultimate strength is not affected, also considerable improvement in durability properties is observed.

GGBS is used as green construction material.

- High rise building construction

- Marine applications such as Dam, Shore protection construction.

- Effluent treatment plant

- Sewage system construction

- Cement products like Pipe, Tiles, Blocks etc.

- Substantially replacement of cement.

Physical properties as per BS 6699:1992

Characteristics

| Specification

| Typical

|

Moisture (%)

| 10 max

| 0.38

|

Fineness

|

|

|

Specific Surface area (m2/kg)

| 275 min

| 395

|

Retention on 45 micron (%)

| No limit

| 2.90

|

Setting time

|

|

|

Initial minutes

| 60 min

| 195

|

Final minute

| No limit | 290

|

Soundness

|

|

|

Le-Chatelier Expansion (mm)

| 10 max

| 1.0

|

Compressive strength

|

|

|

(Mortar) with Portland cement (PC)

|

|

|

2 days-N/mm27 days-N/mm2

| 10.0 min

| 28.3

|

7 days-N/mm2

| No limit | 38.2

|

28 days-N/mm2

| 42.5-62.5

| 47.40

|

(Mortar) with 70% GGBS +30% PC

|

|

|

2 days-N/mm2

| No limit | 10.40

|

7 days-N/mm2

| 12.0 min

| 24.10

|

28 days-N/mm2*

| 32.5 min

| 42.10

|

Glass content (%)

| 67 min

| 94.00

|

Chemical composition as per BS 6699:1992

Composition (%)

| Specification

| Typical value

|

Loss on Ignition (LOI)

| 3.0 max

| 0.65

|

Insoluble Residue (IR)

| 1.5 max

| 0.42

|

Silica as SiO2

| No limit

| 34.52

|

Alumina (Al2O3)

| No limit

| 13.95

|

Iron oxide (Fe2O3)

| No limit

| 0.90

|

Calcium oxide (CaO)

| No limit

| 41.75

|

Magnesium oxide (MgO)

| 14.0 max

| 6.03

|

Sulphur trioxide (SO3)

| 2.5 max

| 0.26

|

Sulphide Sulphur

| 2.0 max

| 0.70

|

Sodium oxide (Na2O)

| No limit

| 0.30

|

Potassium oxide (K2O)

| No limit

| 0.34

|

Chloride (Cl)

| 0.10 max

| 0.01

|

Manganese oxide (Mn2O3)

| 2.0 max

| 0.45

|

|

|

|

Chemical ratio

|

|

|

CaO+MgO+SiO2

| 66.67 min

| 82.30

|

(CaO+MgO)/SiO2

| 1.0 min

| 1.38

|

CaO/SiO2

| 1.4 max

| 1.21

|

Enhanced Performance in ConstructionGGBFS is utilized to boost the strength and durability of concrete structures. Its finely ground nature blends smoothly with cement, aiding in longer-lasting, chemical-resistant constructions. The materials low thermal conductivity and dimensional stability make it suitable for demanding engineering applications.

Safe and Sustainable SupplementWith low toxicity, negligible chloride or alkali content, and high purity, GGBFS is safe for workers and the environment. Sourced from blast furnace slag, it supports sustainable development by recycling industrial byproducts into value-added construction materials.

Versatile Applications and Easy StorageGGBFS is applied as a cement replacement, admixture, or road base stabilizer. Available in bulk or jumbo bag packaging, it can be easily stored in moisture-proof silos or containers to preserve its fine powder quality. Its stable characteristics ensure consistent performance in concrete mixes.

FAQs of Ground Granulated Blast Furnace Slag:

Q: How is Ground Granulated Blast Furnace Slag used in concrete and construction projects?

A: GGBFS is primarily blended with ordinary Portland cement to serve as a supplementary cementitious material, improving concretes compressive strength, durability, and chemical resistance. It is also used in road construction, soil stabilization, and as an aggregate in refractory concretes.

Q: What are the main benefits of using GGBFS as a cement replacement?

A: Using GGBFS enhances concretes long-term strength, reduces permeability, and increases resistance to chemical attack. Additionally, it typically extends the initial setting time, which can be advantageous for large pours or hot-weather concreting, and supports sustainability by recycling an industrial byproduct.

Q: When should GGBFS be added during the concrete production process?

A: GGBFS is generally mixed with the cement and other components during batching, prior to adding water. This ensures thorough dispersion throughout the concrete mixture, promoting uniform performance and optimal strength development.

Q: Where should Ground Granulated Blast Furnace Slag be stored to maintain its quality?

A: To retain its fine powder consistency and prevent moisture absorption, GGBFS should be kept in dry, moisture-proof silos or sealed containers, whether in bulk or in jumbo bags.

Q: What is the chemical composition and physical nature of GGBFS?

A: GGBFS primarily contains 35-42% CaO, 32-38% SiO2, 7-16% Al2O3, and 4-12% MgO, with a specific gravity of 2.9-3.0 and a fine powder or granular form. Its color ranges from light grey to off-white, and it exhibits low porosity, low water absorption, and high purity.

Q: Is GGBFS compatible with other concrete admixtures and Portland cement?

A: Yes, GGBFS is fully compatible with ordinary Portland cement and most modern concrete admixtures, facilitating versatile formulation options for different project requirements.

GGBS replaces a substantial proportion of normal cement OPC in RMC. The mixing varies from 30% to 70% approximately (generally 50%). The higher the proportion, the better is durability for concrete. GGBS is also used in other forms of concrete including site batched and precast.

GGBS replaces a substantial proportion of normal cement OPC in RMC. The mixing varies from 30% to 70% approximately (generally 50%). The higher the proportion, the better is durability for concrete. GGBS is also used in other forms of concrete including site batched and precast. Superior Appearance

Superior Appearance