Calcium Oxide is widely used in various types of industries.

- «AAC block manufacturing

- «Chemical Industries

- «Sugar Industries

- «Paper & pulp Industries

- «Effluent treatment plant

- «Petroleum industries

Light weight block (AAC)

Quick lime is widely used to manufacture light weight block. It reacts with aluminum and formation of hydrogen takes place which increase the volume of mass.

Petroleum industries

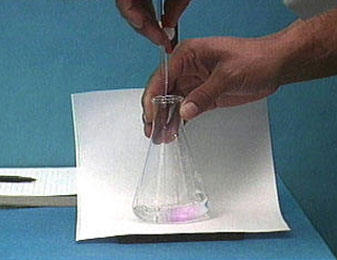

Water detection pastes contain a mix of calcium oxide and phenolphthalein. This paste come into contact with water in a fuel storage tank, the CaO reacts with the water to form calcium hydroxide. Calcium hydroxide has a high enough pH to turn the phenolphthalein a vivid purplish-pink color, thus indicating the presence of water.

Paper industries

Quick lime is used to regenerate sodium hydroxide from sodium carbonate in chemical recovery of Kraft pulp industries.

PACKING

We supply quick lime product as per customer requirement. Normally supply is available either bulker or

jumbo bag packing.

Our laboratory is well equipped with latest instruments for evaluation of product. We perform physical and chemical testing of our product as per IS-1514.

Our laboratory is well equipped with latest instruments for evaluation of product. We perform physical and chemical testing of our product as per IS-1514.